Have Questions?

-

Australian Owned & Operated

-

Technical Support

-

Easy Returns

-

fast & Free Shipping

Foxwell JT400 GDI/EFI/FSI Fuel Injector Cleaner Machine – 4-Cylinder Heated Ultrasonic Tester

Foxwell JT400 Professional Fuel Injector Cleaner & Tester Machine – Ultrasonic GDI Injector Diagnostic System

The Foxwell JT400 Fuel Injector Cleaner & Tester is a high-performance, professional-grade solution designed for automotive workshops, garages, and advanced technicians who demand accuracy, efficiency, and reliability. Built with advanced ultrasonic cleaning technology and intelligent microcomputer control, the JT400 simulates real engine operating conditions to thoroughly clean, test, and diagnose gasoline fuel injectors with precision. Supporting up to 99% of petrol injectors on the market and offering ultrasonic cleaning for diesel injectors, this all-in-one system delivers fast, consistent, and workshop-ready results for modern fuel systems.

NOTICE: For EU customers, orders will be shipped from an overseas warehouse to ensure fast and reliable delivery.

Foxwell JT400 Fuel Injector Cleaner & Tester – Product Overview

The Foxwell JT400 GDI Fuel Injector Cleaner & Tester is a professional-grade automotive diagnostic and cleaning solution designed for workshops, garages, and advanced DIY mechanics. Utilizing ultrasonic cleaning technology combined with precise fuel pressure control, this advanced injector testing machine simulates real engine operating conditions to accurately clean, test, and diagnose fuel injectors.

The JT400 supports 99% of petrol (gasoline) fuel injectors available in the market. For diesel injectors, the machine supports ultrasonic cleaning only (testing functions are not applicable for diesel systems).

Top Reasons to Choose Foxwell JT400 4-Cylinder Injector Cleaner & Tester

● 100W Ultrasonic Cleaning Power: Equipped with high-power ultrasonic technology, the JT400 can simultaneously clean single or multiple fuel injectors. Ultrasonic vibrations effectively remove carbon deposits, varnish, and internal blockages from injector nozzles and internal channels.

● Automatic Control & Real-Time Monitoring: Built-in microcomputer control and digital display allow automatic management of cleaning and testing processes while continuously monitoring system pressure, injector status, and operational parameters in real time.

● 3L Large-Capacity Cleaning Tank: Despite weighing only 12kg for easy portability, the JT400 features a large 3-liter ultrasonic cleaning tank, allowing multiple injectors to be cleaned at once—significantly improving workshop efficiency and saving time.

● Multi-Voltage Injector Testing: Supports multiple voltage outputs (12V, 70V, 120V), making it compatible with various injector types and ensuring accurate testing across different fuel systems.

● Complete Injector Accessories Included: Comes with a wide range of adapters and components to support different injector sizes and vehicle models.

● Eco-Friendly & Wide Vehicle Compatibility: Cleaning and testing fluids can be easily recycled. Compatible with most gasoline vehicles and motorcycles. Supports both 110V and 220V power supplies.

● 2-Year Warranty & Long-Term Support: Foxwell provides free replacement parts for non-human damage within 5 years. Customer support responses are guaranteed within 24 hours.

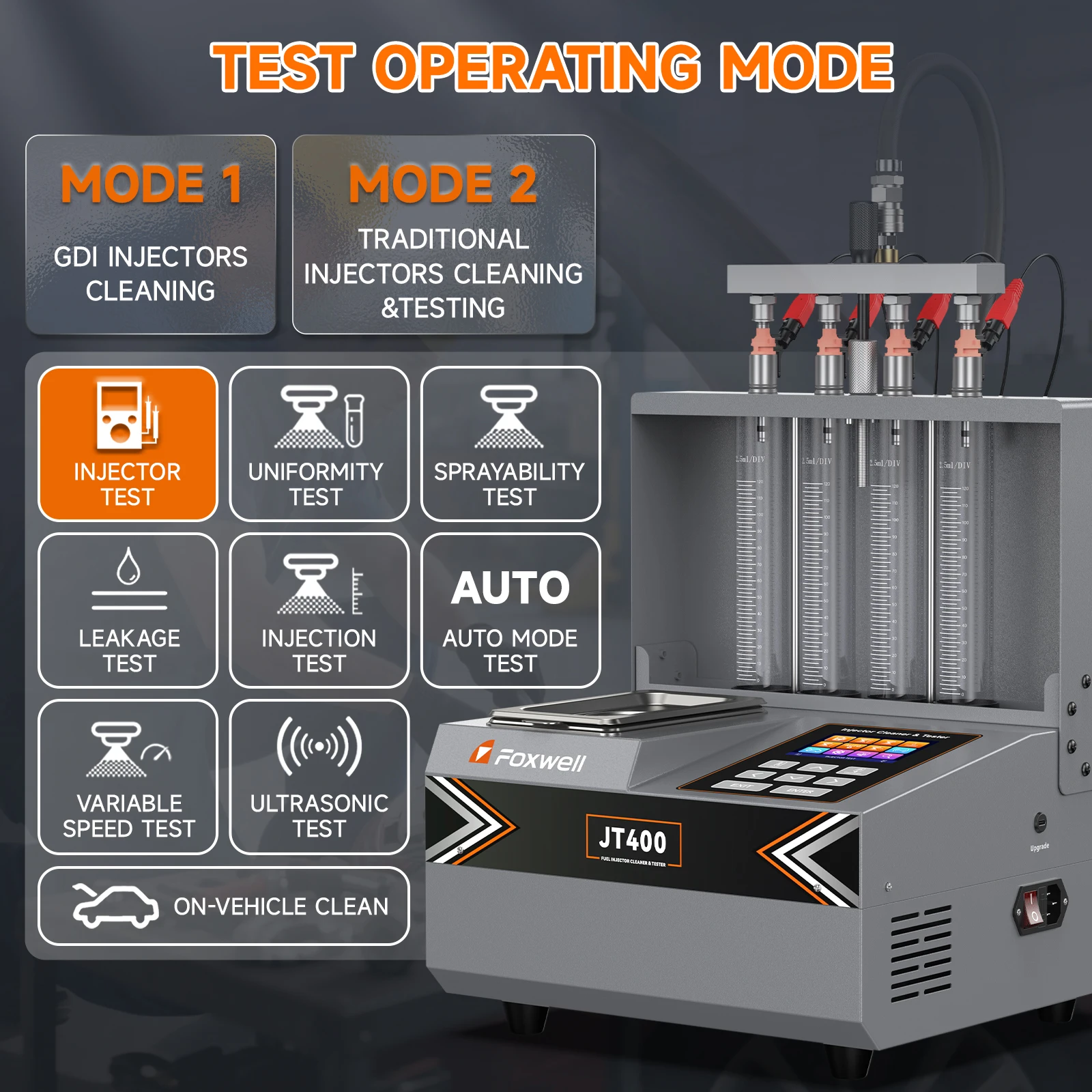

Foxwell JT400 Main Functions

1. Injector Resistance Test – Accurately measures solenoid injector resistance to detect electrical faults.

2. Uniformity Test – Compares fuel injection consistency between injectors.

3. Spray Pattern Test – Evaluates injector atomization performance.

4. Leakage Test – Identifies injector sealing issues under system pressure.

5. Injection Volume Test – Measures fuel output within 10 seconds to verify specifications.

6. Auto Mode Test – Fully automated injector testing based on preset programs.

7. Variable Speed Test – Tests injector performance under varying engine speeds.

8. Ultrasonic Cleaning Mode – Removes internal carbon deposits efficiently.

9. On-Vehicle Cleaning – Cleans fuel system, injectors, and combustion chamber without disassembly.

10. System Settings – Language, units, device info, and factory reset options.

11. Database Function – Built-in fuel pressure database for various vehicle models.

12. Help & Diagnostics – Displays fault codes and operational guidance.

Foxwell JT400 Advanced Design Features

▶ Integrated ultrasonic cleaner design simplifies operation and increases efficiency.

▶ Dedicated motherboard supports extended testing of low-resistance injectors (as low as 1Ω).

▶ Automatic fuel pressure depressurization protects both equipment and operator safety.

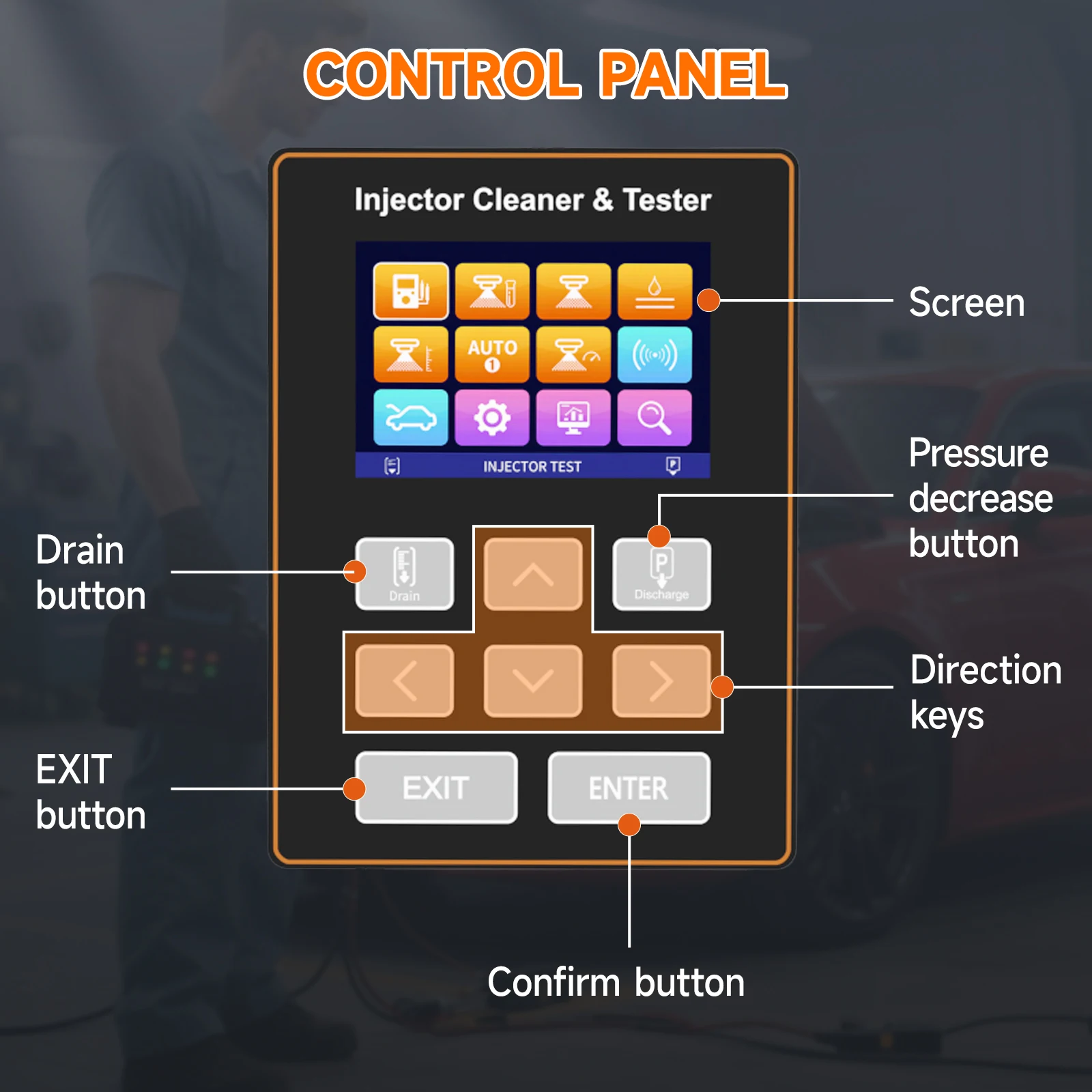

▶ Adjustable screen brightness, backlight, and buzzer volume with memory function.

▶ Microcomputer-controlled fuel pressure regulation ensures stable and precise testing.

▶ Human-centered design allows rapid system pressure recovery and smooth workflow.

Operation Tips & Fluid Selection Guide

Ultrasonic Cleaning:

1. Add injector cleaning fluid and place injectors in the ultrasonic tank.

2. Connect pulse signal wire and activate ultrasonic cleaning mode.

Injector Testing:

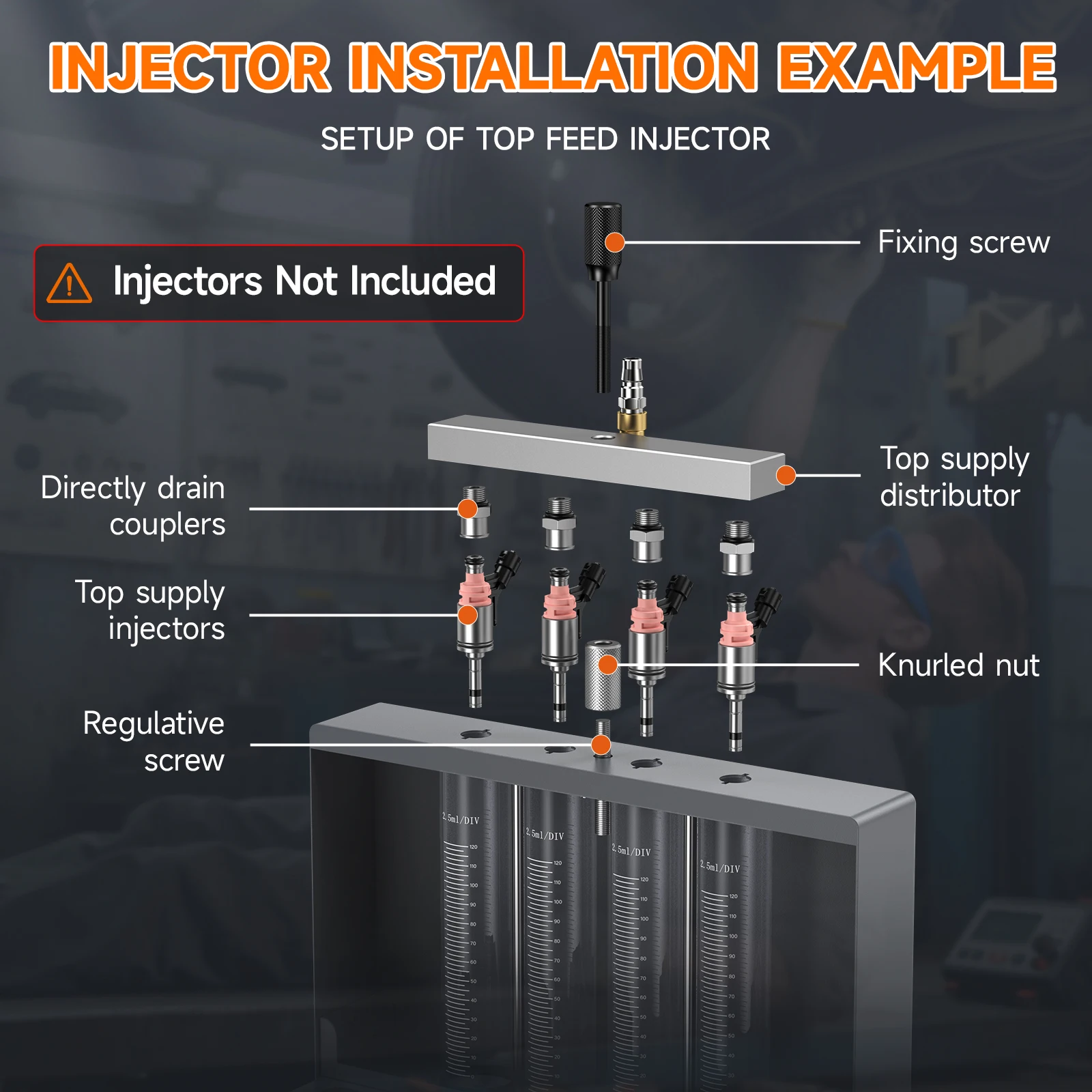

1. Fill test fluid, install injectors on the fuel distributor, and secure the unit.

2. Perform leakage, spray, and injection tests using different modes.

Recommended Test Fluid:

Use professional injector test fluid for best accuracy. If unavailable, medical alcohol (≥75%) may be used as an alternative.

Recommended Cleaning Fluid:

Professional ultrasonic injector cleaning fluid is advised. Alcohol may be used in emergencies, though cleaning efficiency may be reduced.

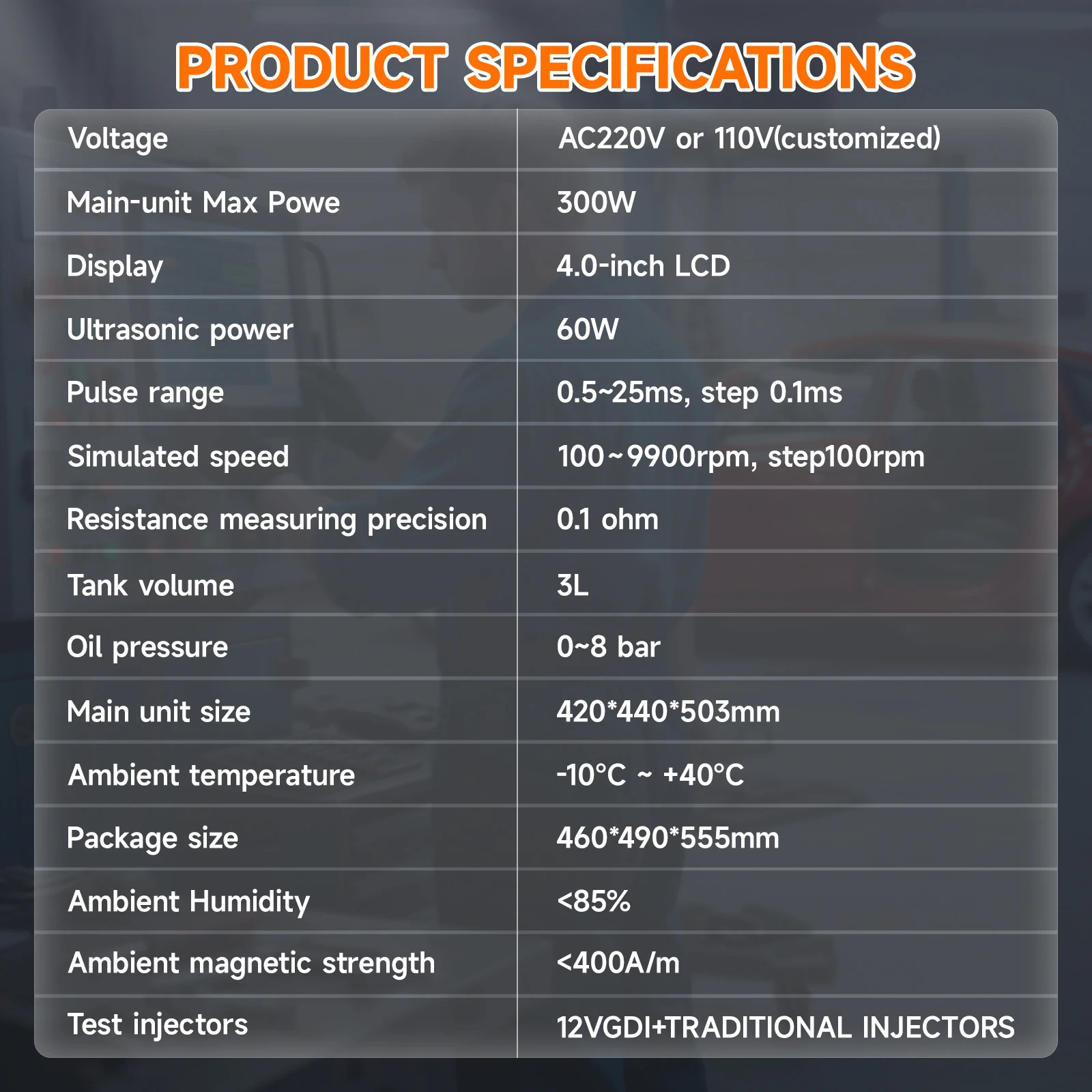

Working Conditions & Technical Specifications

The Foxwell JT400 Fuel Injector Cleaner & Tester is engineered for professional automotive workshops and high-precision injector diagnostics. Its stable operating environment and advanced specifications ensure accurate testing, reliable cleaning performance, and long-term durability.

Power & Electrical Specifications:

Voltage: AC 220V / 110V (Customizable)

Main Unit Maximum Power: 300W

Ultrasonic Power Output: 60W

Display & Control:

Display Screen: 4.0-inch LCD digital display

Pulse Width Range: 0.5–25ms (0.1ms step adjustment)

Simulated Engine Speed: 100–9900 RPM (100 RPM step)

Testing Accuracy:

Resistance Measurement Precision: 0.1 Ohm

Oil Pressure Range: 0–8 Bar

Tank & Capacity:

Ultrasonic Cleaning Tank Volume: 3 Liters

Physical Dimensions:

Main Unit Size: 420 × 440 × 503 mm

Package Size: 460 × 490 × 555 mm

Operating Environment:

Ambient Temperature: -10℃ to +40℃

Ambient Humidity: <85%

Ambient Magnetic Strength: <400A/m

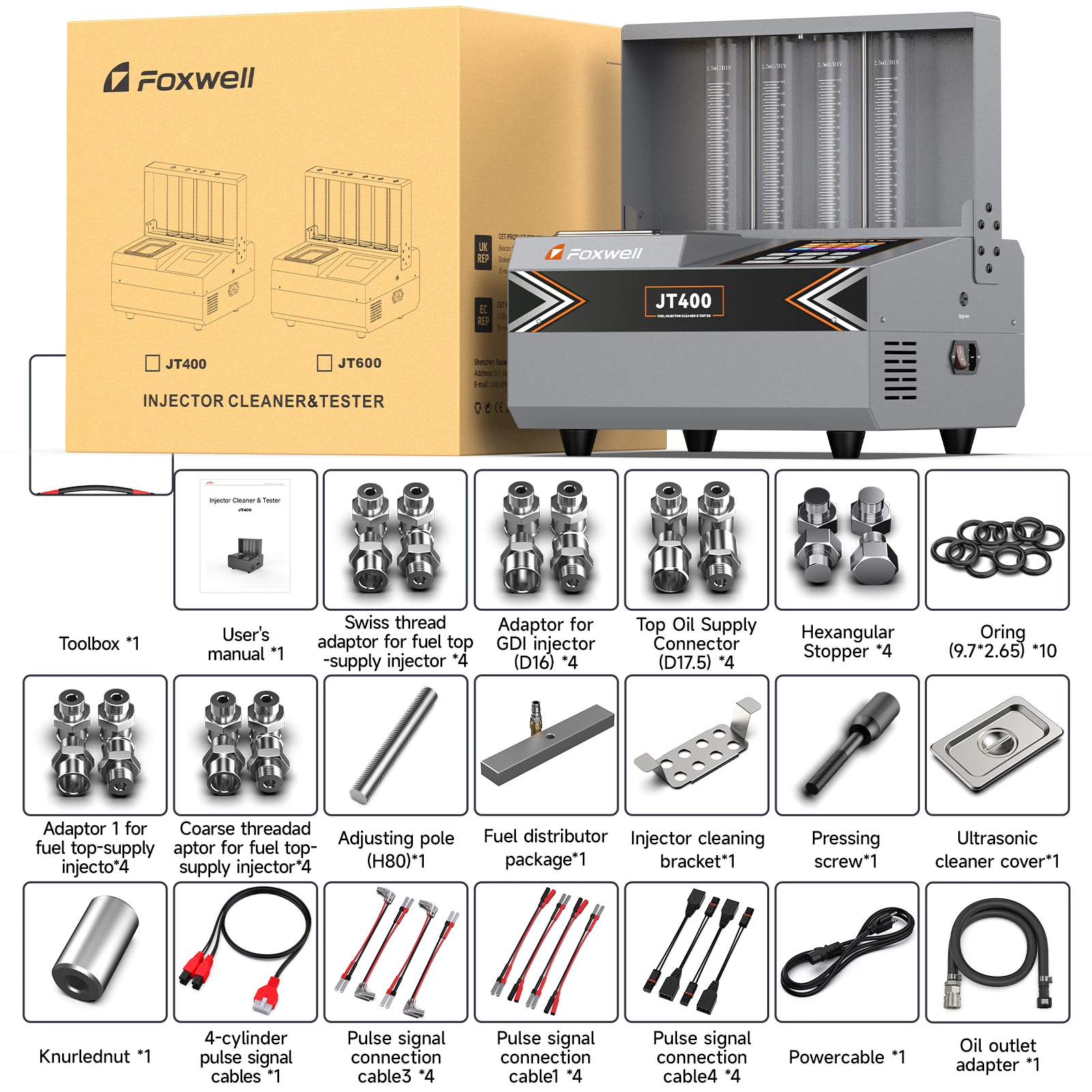

Complete Packing List

The Foxwell JT400 comes with a comprehensive accessory kit, allowing immediate operation for a wide range of fuel injector cleaning and testing tasks.

• Main Unit: 1 Set

• Ultrasonic Cleaner Cover: 1 Pc

• Injector Cleaning Bracket: 1 Pc

• Fuel Distributor Package: 1 Set

• 4-Cylinder Pulse Signal Cable Set: 1 Set

• Pulse Signal Connection Cable 1: 4 Pcs

• Pulse Signal Connection Cable 3: 4 Pcs

• Pulse Signal Connection Cable 4: 4 Pcs

• Adaptor for Fuel Top-Supply Injector: 4 Pcs

• Coarse Thread Adaptor for Fuel Top-Supply Injector: 4 Pcs

• Swiss Thread Adaptor for Fuel Top-Supply Injector: 4 Pcs

• Hexangular Stopper: 3 Pcs

• Adjusting Pole (H80): 1 Pc

• Knurled Nut: 1 Pc

• Pressing Screw: 1 Pc

• GDI Injector Adaptor (D16): 4 Pcs

• Top Oil Supply Connector (D17.5): 4 Pcs

• Toolbox: 1 Pc

• Oil Outlet Adapter: 1 Pc

• Power Cable: 1 Pc

• O-Ring 9.7×2.65: 10 Pcs

• User Manual: 1 Pc