ANCEL ANJ400 GDI Fuel Injector Cleaner & Tester: Comprehensive Description

The ANCEL ANJ400 GDI Fuel Injector Cleaner and Tester is a state-of-the-art, professional-grade diagnostic and maintenance tool designed to revolutionize fuel injector care for gasoline-powered vehicles and motorcycles. Engineered to support a wide range of injector types, including GDI (Gasoline Direct Injection), EFI, FSI, and standard injectors, this 4-cylinder ultrasonic cleaning machine delivers exceptional performance for small to medium-sized repair shops, automotive professionals, and DIY enthusiasts. With its advanced ultrasonic cleaning technology, microcomputer-controlled fuel pressure system, and comprehensive testing capabilities, the ANJ400 ensures optimal injector performance, enhancing engine efficiency, fuel economy, and longevity. Certified with CE, FCC, and ROHS standards, this compact, user-friendly device is a must-have for maintaining modern fuel injection systems.

A powerful, multi-functional machine designed for both cleaning and testing various fuel injectors, including the latest GDI types.

Wide Compatibility

The ANJ400 supports a range of injector types, making it ideal for various vehicle models and systems:

-

Standard Injectors

-

EFI (Electronic Fuel Injection)

-

FEI (Fuel Electronic Injection)

-

GDI (Gasoline Direct Injection) injectors, including:

Advanced Features

-

Multi-voltage support for GDI injectors – adapts easily to different injector types

-

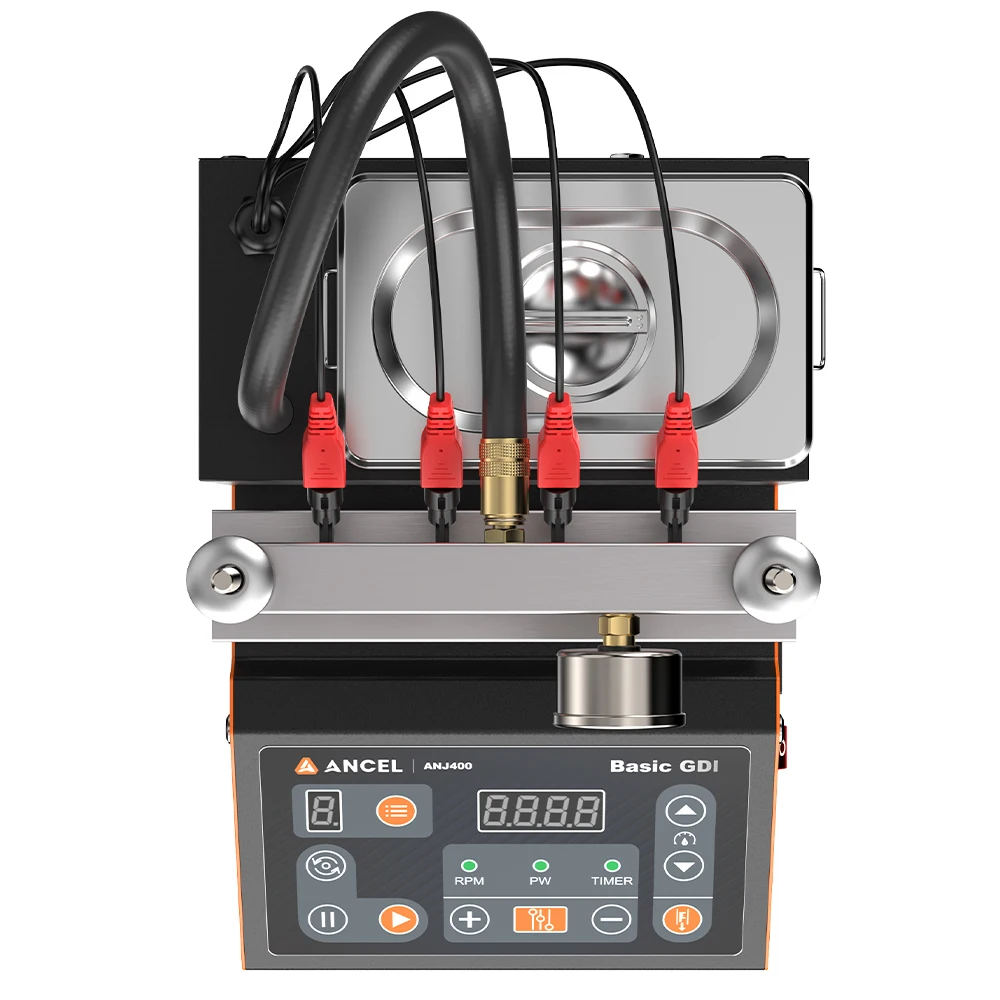

Simultaneous cleaning and testing for up to 4 injectors

-

Pulse and pressure control system for accurate diagnostics

-

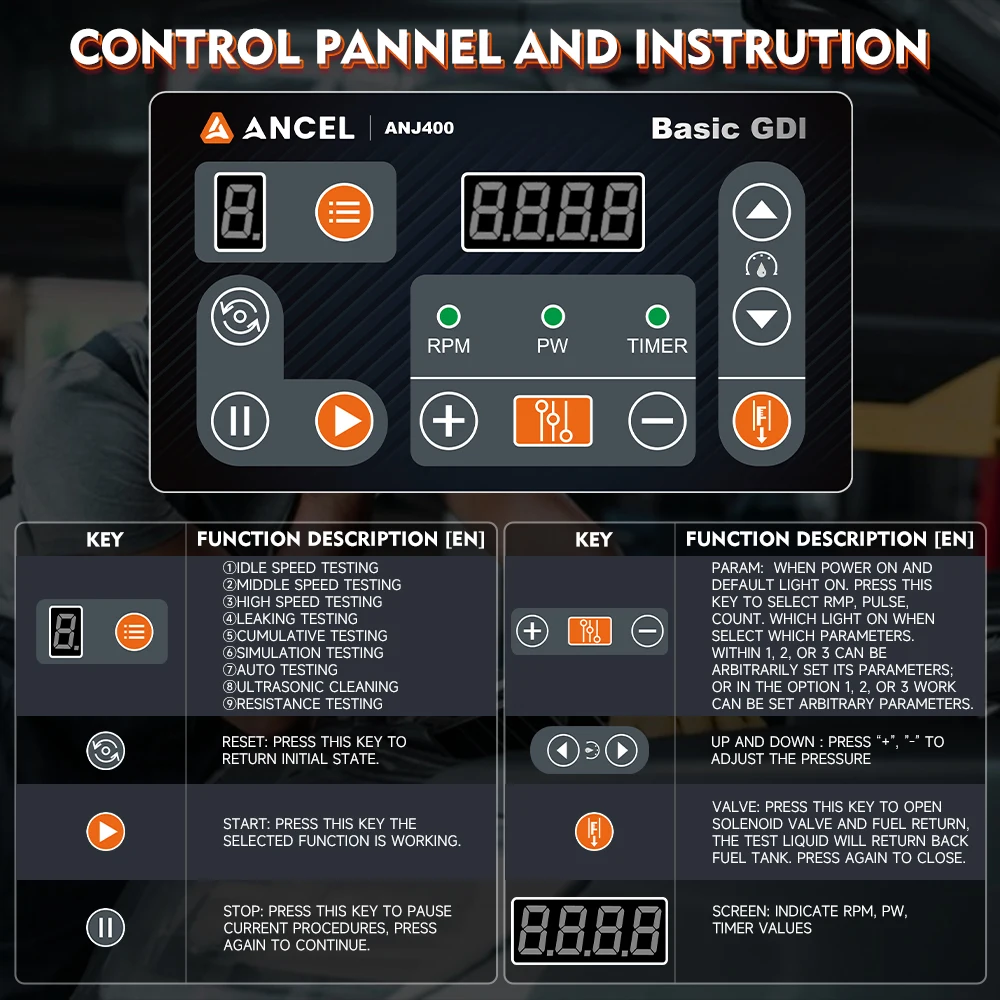

Clear display panel for easy operation and result tracking

-

Compact and durable build, ideal for both workshop and educational environments

Ideal for Multiple Uses

Perfect equipment for:

-

Automotive repair workshops

-

Vehicle maintenance centers

-

Automotive research labs

-

Technical training and teaching institutes

-

Motorcycle and small engine services

Usage Notes

Ancel ANJ400 GDI Fuel Injector Cleaner & Tester – Key Features

1. GDI, EFI, and FEI Injector Cleaning & Testing

The ANJ400 is designed to clean and test a wide range of fuel injectors, including:

-

Standard injectors (EFI, FEI)

-

GDI (Gasoline Direct Injection) injectors

Compatible with vehicles from:

2. Multi-Voltage Selection for GDI Testing

-

Features multiple voltage output options:

-

Allows testing of different types of injectors with voltage flexibility

-

Ensures safe and accurate testing for a wide range of vehicle systems

3. High-Powered Ultrasonic Cleaning

-

Equipped with 100W ultrasonic cleaning power

-

Stronger ultrasonic waves for deep internal cleaning of fuel injectors

-

Effectively removes carbon buildup and fuel residues

4. Equipped with Multiple Accessories

-

Comes with various injector adapters and fittings

-

Supports multiple vehicle types and injector models

-

Ready-to-use for different cleaning/testing needs without extra tools

GDI Fuel Injector Specialist

This machine is specially built for servicing modern engines that use Gasoline Direct Injection (GDI) technology. It ensures:

-

Precise spray pattern testing

-

Reliable flow rate checking

-

Effective internal and external injector cleaning

The ANJ400 is a must-have tool for auto technicians, repair shops, and automotive educators.

Ultrasonic Cleaning Function

It works by sending an ultrasonic vibration signal to the injector through the pulse signal cable, which causes a strong vibration of the carbon inside and thus enables more thorough cleaning.

Introduction

Fuel injectors are critical components in every gasoline engine, directly impacting power output, fuel efficiency, and emissions. Over time, poor-quality fuel or prolonged low-speed operation can lead to carbon deposits, blockages, and leaks, resulting in unstable idling, increased fuel consumption, weak acceleration, starting difficulties, and excessive emissions. In severe cases, clogged injectors can cause irreversible engine damage. The ANCEL ANJ400 addresses these challenges by combining powerful ultrasonic cleaning with precise diagnostic testing, offering a cost-effective, efficient, and environmentally friendly solution to restore and maintain injector performance.

Priced competitively for an entry-level professional tool, the ANJ400 is ideal for gasoline cars and motorcycles, including those with advanced GDI systems found in brands like Mercedes-Benz, BMW, Audi, Porsche, and Ford. Its compact design, intuitive operation, and robust feature set make it a versatile choice for both professional workshops and DIY users looking to save on costly repairs and injector replacements.

Key Features and Benefits

The ANCEL ANJ400 is packed with advanced features that set it apart as a leading fuel injector cleaner and tester. Below is a detailed overview of its capabilities:

1. Advanced Ultrasonic Cleaning Technology

-

Powerful Cleaning: The ANJ400 utilizes ultrasonic cleaning to generate penetrating and cavitation shock waves in a 1300ml cleaning tank, effectively dislodging stubborn carbon deposits and impurities from injectors with complex shapes, cavities, and pores. This gentle yet thorough process ensures complete removal of blockages without damaging delicate components.

-

Eco-Friendly Operation: Unlike traditional cleaning methods that rely on chemical solvents, the ANJ400’s ultrasonic technology minimizes environmental impact, making it a sustainable choice for modern workshops.

-

Heating Function: The machine includes a heating feature that warms the cleaning solution to 40°C, enhancing cleaning efficiency and reducing processing time.

-

Integrated Cleaning Tank: The ultrasonic cleaner is built into the machine, streamlining operations and improving workflow efficiency.

. Comprehensive Injector Testing Capabilities

The ANJ400 offers a wide range of diagnostic tests to evaluate injector performance under various conditions, ensuring accurate diagnosis and optimal functionality:

-

Resistance Test: Measures the resistance of each injector (with 0.1Ω accuracy) to identify electrical faults, shorts, or current draw issues.

-

Leakage Test: Assesses the sealing and dribbling conditions of injectors under system pressure to detect leaks that could affect performance.

-

Injecting Flow Test: Quantifies the injection volume of each injector over 15 seconds of constant injection, ensuring consistent fuel delivery.

-

Uniformity/Sprayability Test: Evaluates the uniformity of fuel injection across all injectors and monitors spray patterns using a backlight for clear visualization, ensuring smooth atomization.

-

Working Modes Test: Simulates various engine operating conditions, including:

-

Idle Speed Test (0-20ms): Tests injector performance at low RPM.

-

Medium Speed Test (0-7.5ms): Evaluates injectors at moderate RPM.

-

High-Speed Test (0-4ms): Assesses performance under high RPM.

-

Acceleration Test: Simulates rapid throttle changes.

-

Deceleration Test: Tests injector response during slowdown.

-

Variable Speed Test: Evaluates performance across a range of speeds.

-

Reverse Cleaning: Flushes injectors in the opposite direction to remove internal debris, enhancing cleaning effectiveness.

-

On-Vehicle Cleaning: Includes a variety of disassembly-free cleaning connectors, allowing maintenance directly on the vehicle for added convenience.

Whats in the BOX

- ADJUSTED SCREW

- FUEL FEED FUNNEL

- SPECIAL LINE

- POWER LINE

- TOP ULTRASOUND

- SUPPORT FRAME OF INJECTORS

- SEALED RING OF CONNECTORS (7.52X3.53)

- TOP FEED INJECTOR RAIL

- R1/4BLANK PLUG

- EUROPEAN STANDARD CONNECTORS13.6

- CONECTOR DE INYECTOR9.8 (GDI CONECTOR)

- CONECTOR DE INYECTOR12.5 (GDI CONECTOR)

- CONECTOR DE INYECTOR18 (GDI CONECTOR)

- CONECTOR DE BENZ MECHANICAL INJECTOR (M12X1.5)

- 11 UNDERLAY OF INJECTOR

- INJECTOR PLATE14 FLAT PLATE

Microcomputer-Controlled Fuel Pressure System

-

Stable Pressure Control: The ANJ400 employs microcomputer fuel pressure adjustment technology to maintain stable fuel pressure (0-7 bar) across a wide adjustable range, ensuring compatibility with various gasoline injection systems.

-

Automatic Depressurization: A unique fuel circuit depressurization feature automatically reduces pressure during sudden shutdowns, preventing equipment damage or personal injury.

-

High-Quality Oil Pump: The machine uses a durable oil pump to ensure long-term stable operation, even under demanding conditions.

User-Friendly Design and Operation

-

Digital Display and Controls: The ANJ400 features a high-definition LED display, pressure gauge, glass tubes, and a multifunctional control panel for real-time monitoring of injector performance and fuel dynamics. Clear menus and intuitive controls simplify operation for users of all skill levels.

-

Customizable Settings: Adjust screen brightness, backlight, and buzzer volume to suit your preferences, with settings saved for future use.

-

Efficient Fuel Separator Design: A specially designed fuel separator allows quick disassembly and assembly, improving work efficiency.

-

Wide Compatibility: Supports standard injectors, GDI injectors, EFI, and FSI injectors, covering over 98% of gasoline-powered cars and motorcycles, including direct injection systems.

-

Compact and Portable: The ANJ400’s compact size makes it ideal for small workshops or home garages, while its robust construction ensures durability.

Low-Resistance Injector Support

-

Dedicated Motherboard: The ANJ400’s specialized motherboard supports extended testing of low-resistance injectors (e.g., 1 ohm), ensuring compatibility with a wide range of injector types without risk of damage.

-

Safe Operation: Internal over-current protection prevents damage to injectors during testing, enhancing reliability.

Environmental and Safety Features

-

Replaceable Ultrasonic Cleaning Tank: The main board of the ultrasonic cleaning tank can be replaced if damaged, extending the machine’s lifespan and reducing maintenance costs.

-

Safe Fluid Handling: The machine features a manual liquid discharge method with a built-in slope design to filter impurities, ensuring environmentally friendly operation and cost savings.

-

Certifications: Compliance with CE, FCC, and ROHS standards guarantees safety and quality.

Why Choose the ANCEL ANJ400?

The ANJ400 is a versatile, cost-effective solution for maintaining fuel injectors, offering several key advantages:

-

Enhanced Engine Performance: Regular cleaning and testing prevent carbon buildup, restoring power, improving idle stability, and reducing fuel consumption.

-

Cost Savings: By avoiding injector replacements and reducing reliance on professional services, the ANJ400 saves money for both shops and DIY users.

-

Environmental Benefits: Ultrasonic cleaning reduces the need for chemical solvents, minimizing environmental impact.

-

Broad Compatibility: Supports a wide range of injector types and vehicle models, making it a versatile tool for diverse applications.

-

Ease of Use: The intuitive interface, automated processes, and comprehensive accessories make it accessible to all users, from novices to professionals.

Operation Process

The ANJ400’s operation is straightforward, ensuring efficient cleaning and testing. Follow these steps:

-

Preparation: Clean the exterior of the injectors with gasoline or cleaning fluid before operation.

-

Ultrasonic Cleaning: Place injectors in the ultrasonic bathtub and activate the system to remove internal debris and carbon deposits.

-

Injector Installation: Secure injectors on the main machine for testing.

-

Electrical Testing: Perform resistance, shorts, and current draw tests.

-

Performance Testing: Conduct leak, spray pattern, and flow rate tests on the flow bench.

-

Retesting: Return injectors to the flow bench to verify all functions post-cleaning.

Recommended Cleaning and Testing Sequence

For optimal results, follow this sequence:

-

Ultrasonic Cleaning

-

Uniformity/Sprayability Test

-

Leakage Test

-

Injecting Flow Test

-

Working Modes Test

Post-Operation Procedure

-

Drain the test solution into a fuel container.

-

Switch off the power and unplug the machine.

-

Remove residual cleaning fluid from the ultrasonic pool and wipe it dry.

-

Clean the machine’s tabletop with a soft, dry cloth.

-

Dispose of used test fluid according to local regulations or store reusable fluid safely.

Fluid Selection Guidelines

-

Test Fluid: Use professional automotive injector test fluids for accurate results. If unavailable, medical alcohol (75%+) can be used as a substitute, though results may be less optimal. The test fluid should be colorless, non-corrosive, and odorless to simulate injector performance accurately.

-

Cleaning Fluid: Opt for professional ultrasonic cleaning fluids to remove carbon deposits effectively. Alternatively, 75%+ medical alcohol can be used, but it may be less effective. Avoid corrosive fluids, as they can damage the machine’s components.

Specifitions

Power supply: AC110V±10% or 220V±10%

Input power: 230W

Ultrasonic cleaner power: 100W

Frequency: 50-60HZ±10%

Resistance test accuracy: 0.1Ω

Simulated RPM range:100 ~9900rpm, step: 10rpm

Relative humidity: <85%

Ambient temperature: -10℃~+40℃

External magnetic field strength: <400A/m

No open flames within 2m